Electrical and Navigation Systems

We needed things to get us to places and ways to make things work (like the icemaker). This involved updating our …

The Electrical Work

July 2019

We started thinking and planning the electrical work - which like everything else, has not had much attention for some time. I knew it was urgent when Patrick pointed out

“this is old household wire, from the 60’s, and not suitable for boating” (May 2016)!!.

We will run two systems - 230V AC from shore power or generator and 12V DC. Over breakfast this weekend, we put together a professional diagram of the AC circuits - two separate circuits and 14 double sockets. Seems simple enough, according to the sketch above! Now we need to find an electrical man and a decipherer!

The Plan

August 2019

Have put together a better plan for the AC electrical circuits - well it’s the same plan except this time it is slightly more legible (slightly) and might be enough to convince an experienced electrician that this is not an impossible task.

So we will have two circuits and then separate outputs for certain “appliances/units”

Circuit 1 comprises double sockets, some of which will have USB options, in main saloon area and in front bedroom area.

Circuit 2 is towards the back of the boat and into galley.

Separate outputs for the day fridge, fridge/freezer which will be in a locker under the seating area in galley and the oven. We will also have separate units for the hot water unit, water maker and a battery charger.

The electrical panels arrived by post today, ready to make up the circuits detailed above. These include a DC distribution panel with 22 switches plus the master switch. AC power source selector - shore power or generator. Primary circuit breaker. All to replace what is already on the boat.

These will be handed, along with an AC distribution panel, to the first marine electrician we can convince to do the work.

We also ordered and received our new Kus gauges. As we have two new fuel tanks and two new water tanks, we needed new gauges. We are also fitting a holding tank which will need monitoring and we are going from physical mechanical links from the engine to electrical gauges. So our Kus delivery comprised 2 fuel gauges, 2 water gauges and the holding tank gauge. Also an engine oil pressure gauge as well as gauges for the gear box oil pressure, engine temperature and the ammeter. We will keep the original rev counter.

October 2020

Having found electricians brave enough to take on the job, we started the electrical refit on Deux this weekend. We took their advice and agreed: “rip it all out and start fresh”. There really was very little worth salvaging - between the melted wires and the cracked exposed cables. I am also not sure I believe them when they say they have seen worse.

Now we have new AC and DC distribution panels, new switches, new wiring and willing electricians, it made sense to put this all together in a new wood electric board. So Patrick printed out templates of all the panels and switches and created a template which will be used to make the electric board. It took a couple of modifications and changes, but I think it is going to look great once it is completed and fitted.

November 2020

The electricians returned this weekend (which is a good start) and worked all weekend. So far - so so good. Two banks of new batteries (one for engine and one for domestic use) have been fitted as well as the the new Sterling Pro Battery charger, 60 Amp. The cables for these were installed and taken up to the battery selector / isolation switch and up to the DC distribution panel.

The AC power coming into the boat received a lot of attention, with a focus on safety. The cabling was replaced and a new RCD switch fitted. The power is taken to the panel to the selector switch (generator or shore power), then to main switch and up to AC distribution panel.

A new RCD switch has also been fitted for the generator (to be installed at a later date).

A new bilge switch was installed (one of three).

In the next coming weeks we will have the circuits and wiring to various points fitted, for both AC and DC use - lights, sockets, ice maker!

January 2021

Our inverter arrived, with the vital task of running the icemaker while we are underway (so we don’t have to run the generator). It is 3000w pure sine inverter and the plan was to wire it into the distribution panel and we would just plug in the icemaker as needed.

Patrick had a quick re-think (and discussion with the electrician) and a change of plans. They decided to wire it so it could power the whole AC system. So Patrick replaced the rotary switch, it connects directly to the batteries with its own isolation switch and fuse and not only provides me with ice, it also powers and charges laptops and phones.

January 2021

Now we have new and extra gauges AND willing electricians Patrick looked at replacing the existing main instrument panel. This will allow for the gauges both port and starboard fuel tanks, both water tanks, waste tank, anchor and nav lights. Rev counter, gearbox and engine oil pressure, ammeter, engine temperatures, and then switches for the blower, AIS silent mode, wiper blades and the start and ignition switches. A couple of frustrating hours to get these to all fit into the existing space but he got it done.

February 2021

The new instrument panel arrived! Patrick sanded and varnished the existing (and original) frame and fitted it all together. Then it was up to the electricians to connect all the gauges. The rev counter needed a new cable, so we will have to wait for that to arrive and be fitted

September 2022

We finally reached a point where we could say …. “well that’s all the electrics done now ”. It was a huge job and we had underestimated how much needed to be done and how long it was going to take (Covid19 and lockdown didn’t help), but we got there, with some amazing help.

All in all we now have a number of sockets in the aft/galley section including a socket for the fridge/freezer in the back locker. We have solar panels (the fitting/installation of these is still on the to do list) and these will be wired up to dedicated batteries in the aft section. We have lighting and “fan sockets” in the galley/aft section. The generator has been fitted and wired in (for generator updates see here). All of this has been tested and signed off - including the sockets for the icemaker, which can be powered by the generator, shore power or the inverter.

The icemaker gave its stamp of approval…

Navigation System

Our existing navigation system comprises a compass and a Raymarine ST6000 autopilot. And the use of a mobile phone !!

Needless to say, this needed to be upgraded. We needed a system that will allow us to use electronic charts, for both UK coast and inland waterways of Europe as well as the coast of the Black Sea and the Mediterranean. We also needed a more effective way to use the autopilot and a safer way to navigate the busy European waterways.

So, after more time than I thought necessary, Patrick finished his on-line searching, placed a LOT of orders and then he sat back, waiting for all the “goodies” to arrive;

NMEA 2000 backbone, 15.6 inch touch screen monitor (12 volt), AIS transponder, AIS converter, Garmin display unit, DSC radio, RasberryPi plus HAT (Hardware Added on Top). Shout out to SeaBits (Steve Mitchell) for his comprehensive website and on line advice!

The Rasberry pi runs open CPN and signalK software. It allows us to enter a route and let the autopilot take over.

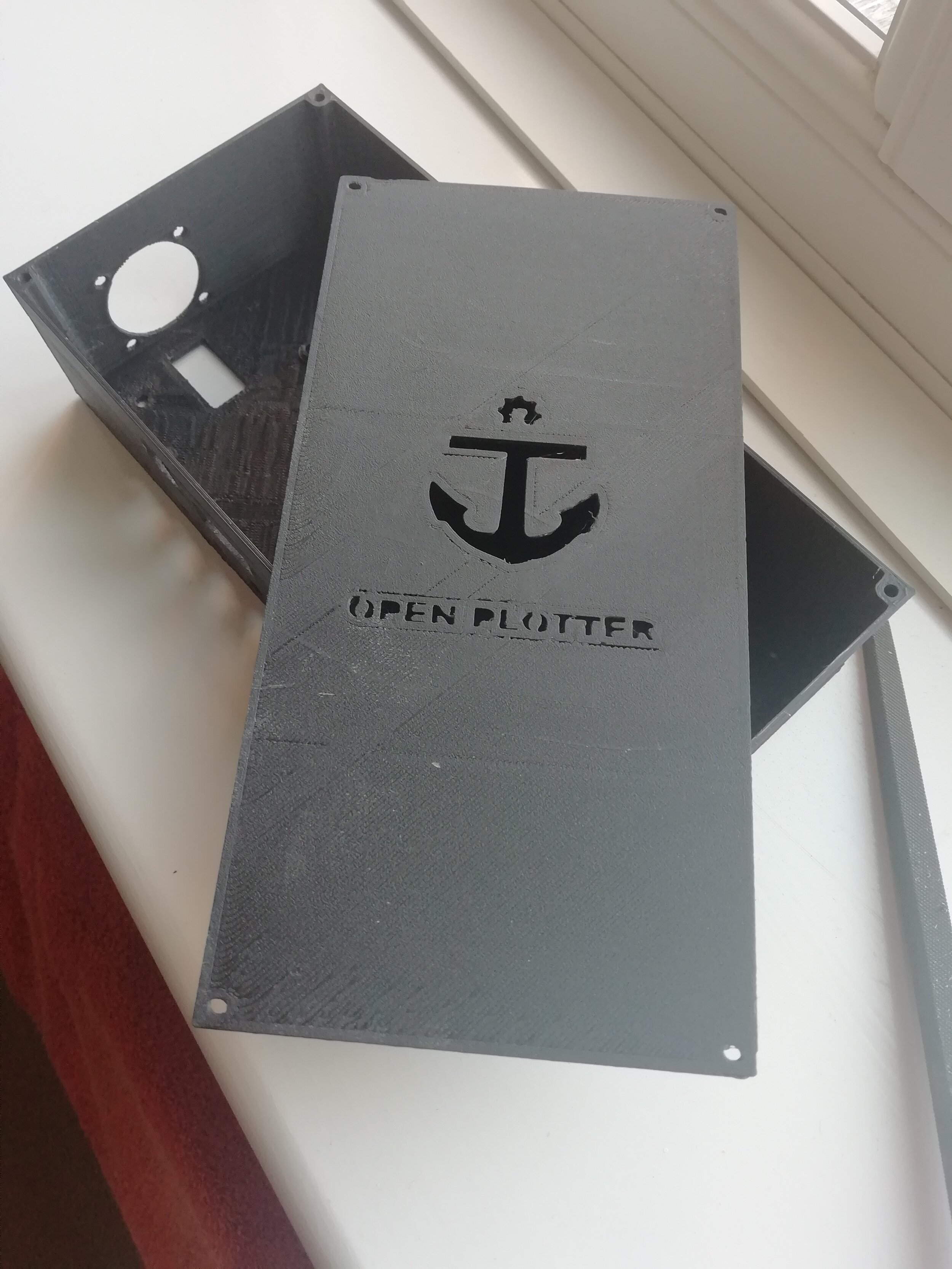

[We convinced my son, who had access to a 3D printer, to make us a RasberryPi box - you would think that a box would be part of the deal !!]

The AIS system allows us to see vessels around and more important, other vessels can see us in busy European waterways. It also means that our position will be updated on sites such as Vessel Finder and friends and family can “find us”.

I had Patrick explain how this all works together (mainly so he could justify the amount of money these few boxes cost!) See below…

August/September 2021

Now came the job to fit all of these bits together so they work as one. We have space in the electric cupboard, so first a large white board to hold all the units. Fitting all the bits was tricky and then they needed to be connected up to make sure it all worked. It was a long job that took patience and expertise beyond Patrick’s remit, but nothing our wonderful electrician couldn’t handle. We were thrilled to see the autopilot work, even though we were still tied up and not going any where.

We have this great marine stereo (Fusion MS-RA210) and we need to find a spot for it. We are leaving the existing speakers as they work really well - so that’s part of the problem solved. I am looking forward to having something else to listen to, besides all moaning and groaning from both me and Patrick !

November 2022

Included in the huge instrument order placed last year were two antenna, which will eventually join the others on our new mast. These antenna will provide us with internet connection. Patrick settled down this week to get this all connected up and ensure that it worked. It did mean removing the panel from the electrical cupboard on the boat and set it all up in the kitchen at home, but I was getting used to this now! It is an impressive set up and I was pleased to see it in action.

Setting up and testing 4G internet connection

February 2023

The autopilot which was fitted on Deux when we bought her became less and less reliable and we finally agreed that it was time to replace it (disguised as a Christmas present). We really wanted some thing we could depend on and be able to step away from the helm for a few minutes. We had also replaced and fitted all new navigation equipment, so it made sense to replace this last piece. Oh well - in for a penny, in for a pound!! It also kept Patrick busy for a whole weekend … so there’s that.

Solar System

We are looking at 480W in total with our flexible solar panels; 3 x 100w panels and 2 x 75w panels, all fitted to the top roof. The 3 x 100w panels will charge our lithium batteries through a victron solar charger, which will keep our (day) fridge and fridge freezer running. The 2 x 75w panels will charge the domestic batteries. We will also have a battery to battery charger, from domestic to lithium.

While we have plenty of space for all the panels, we also have a large hatch that opens up and will cover three 100w panels when fully open, so the two 75w panels alongside the hatch, which are not compromised when the hatch opens, are a real necessity (to keep the lithium batteries going for our fridge).

(The solar panel plan - click the diagram to open fully)

June 2022

The 3 larger panels arrived safely in the post on a convenient sunny day and Patrick got to test (play) for a few hours.

August 2022

We took a weekend off from all the boat work and went over to the Isle of Wight. We anchored for the weekend and it was glorious and hot. Patrick connected one solar panel up to the batteries and this kept the fridge running the whole weekend. This was a successful “test run” and I had chilled wine all weekend! The fridge has a small freezer section and I had ice from there too.

May 2023

With the promise of sunshine and summer days, we spent the weekend fitting the 3 larger solar panels and connecting up that part of the system.

The panels are SunStore Solar Power Solutions (Model No SGM-LEE-100W) and are flexible boat solar panels. We chose these as an option because we can walk on them (should we need to), they fit the space available and they meet the curve of the deck so don’t compromise the look of the boat. They are also 23V panels, so in shady conditions we still get a high voltage into the solar charger. As we are spending a lot of time on canals and rivers, we are likely to be in shade from trees quite a lot.

Patrick used M3 VHB double sided tape. You really only have one shot at sticking the panel down with no chance to re-lift and adjust - it really is impressive stuff. We ran them in series so we could use smaller cables, which attach to the roof of our main saloon. Running in series accumulates the voltage to about 66V in total, but the current remains at 5amps. Patrick will fit a false ceiling to cover the cables (eventually).

Patrick got the three 100w solar panels installed and connected up and got to watch them in action!