The Generator

The Work:

We bought Deux with a generator already fitted in the engine room behind the main engine. This Petter AC1W, with 3 kw generator attached, is a single cylinder engine, which runs at 3000 rpm and without a cover or insulated engine room, was very noisy.

The generator never really worked properly, although it had turned over and started a few times, so gave us some hope that may run after some TLC.

At first, we checked the fuel system, replaced the fuel filters and this worked for a while and the generator ran for a few noisy hours. Then we noticed water in the oil. Discovered that the seal on the shaft for the water pump was leaking and allowing water into sump. Removed water pump, replaced the seal and flushed it out with flushing oil, replaced oil filter and tried again, with the same result.

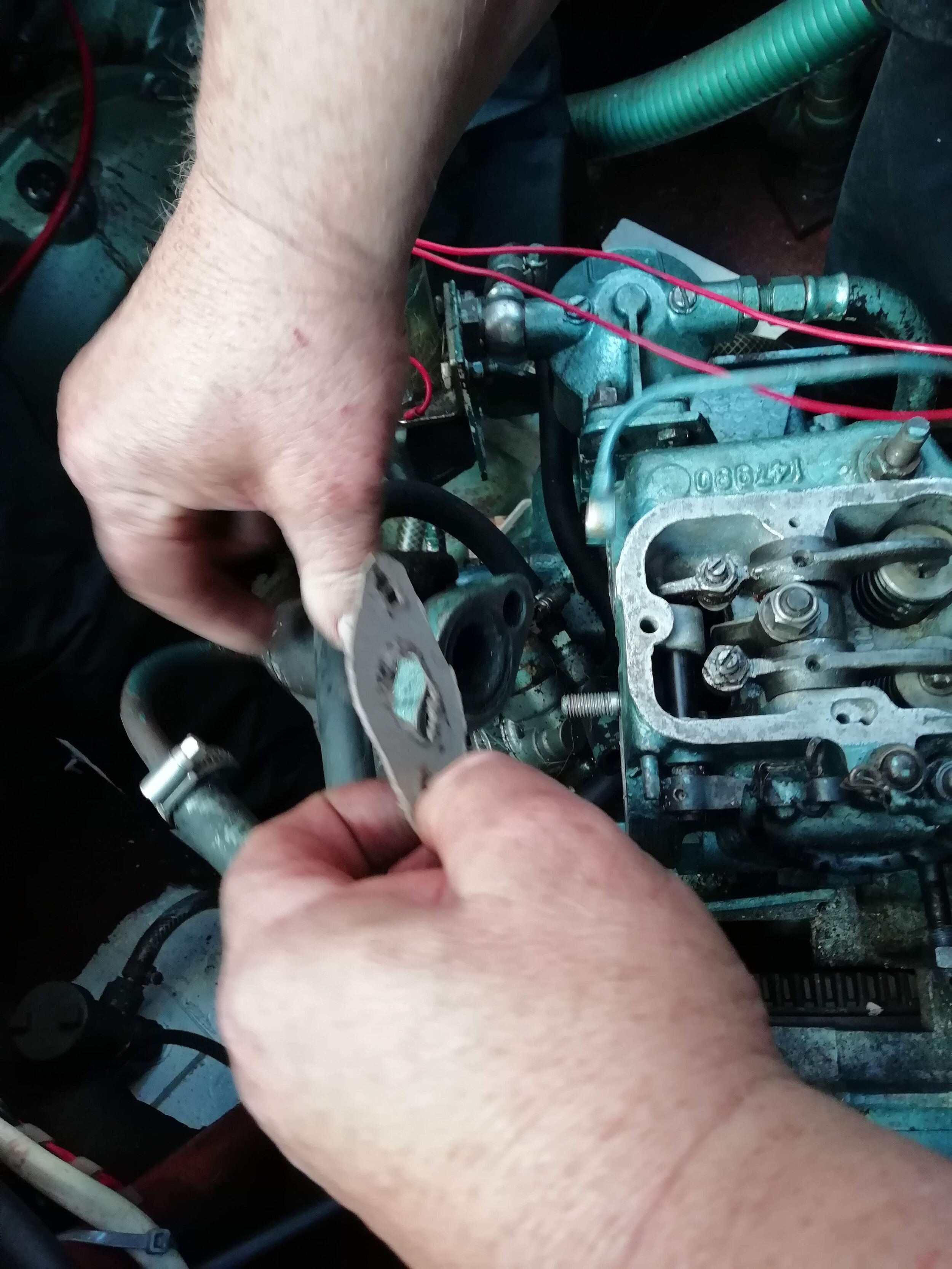

We then decided to take the head off and found extensive corrosion, due to exposure to raw sea water used for cooling. The head was sent off to be repaired and skimmed. After fitting with a new gasket, we tried to restart her, but it was no good - all our best efforts, but she never started!

It was likely due to no compression from a possible crack or the piston rings were damaged.

The generator was lifted out with the main engine, with a view to replace with a new 3 cylinder generator, running at 1500 rpm, so quieter. We are still undecided which generator to buy, so at the moment the "wish list" just states "generator" and is also pretty far down the to-do list and the budget.

Making a “gasket plan”

Nope. Sadly it looks like this is over for her …..

November 2020

We conceded, gave up and Patrick took to what was becoming his favourite past-time / avoidance tactic = internet searching for something boat related, with a focus on replacing the generator.

After what must have be an infinite amount of clicks, we found one. It needed to fit into the available space we had in the engine bay, so it took a while to find. This is a Mitsubishi diesel engine and Sincro generator and with some slight modifications Patrick assured me that it will “just slide in”.

August 2021

Now that the tanks (fuel and water) and engine are all settled into the engine bay, it was time to “wake up” the generator which had been in storage for almost a year. We had to replace the solenoid and after a quick fiddle, she turned over - phewwww!.

Patrick dropped the exhaust pipe a few inches and moved the air filter and now she should fit into the engine bay. We also need a tray made. Something that will be bolted into the engine bay, something that the generator can be bolted to and in the event of a fuel leak (never say never), something to catch the leak.

Patrick drew out the template and Solent Welding and Fabrications were happy to do it for us.

October 2021

Solent Fabricators once again provided excellent service and delivered our drip tray ready for the fitting of the generator in a few weeks.

Then it was time to “drop” the generator in through the top hatch / roof of the boat. It was slightly less stressful compared to when we had the main engine lowered in through the hatch as the generator is considerably smaller.

I did, however, hold my breath as it was lowered down and into position in the engine bay. The generator needs to slide underneath a steel beam and we knew we were working with millimetres to get it in. Patrick did some modifications - turned the air filter on its side and moved the regulator. It worked !! She slid in (with millimetres to spare). Now she needs to be connected up she can get to ready to do some work .

April 2022

Some of the bits we need to get the generator connected arrived in the post today

September 2022:

Switched our attention to the generator this week. Patrick has exhausted his research and any available reading on connecting her up - fuel, water and electrics and he is confident that he can (attempt to) get it right. I have faith in his ability …. and I have our electrician on speed dial, so I think we are good.

The fuel comes from the port side tank and first passes through a dedicated racor fuel filter. At first Patrick fitted a manual fuel pump, but it wasn’t sealing properly and sucking in air. He replaced this with a 12V pump, connected to the generator ignition switch. This was so much better and now there is constant fuel pressure and the engine runs at a constant speed of 3000rpm.

The exhaust goes into a water separator and then out through the side of the hull. This exhaust outlet is just above the water line, level with the engine and with wave action, water is almost certainly going to come back in up the exhaust. Patrick fitted a seacock on the exhaust and so when the generator is not in use, we can close the seacock and stop all that from happening.

The raw sea water cools the engine fresh water via a heat exchanger.

It was a relief to find a generator to fit the (tiny) space available and a joy to hear it turn over and start …. !

Now we know it fits into the engine bay AND starts, Patrick ran the cables up to a space on the side of the hull, for a temporary fixture.

April 2023

Every little space on this boat is used for something. Patrick made a wooden box for the generator control panel and fitted it in the space behind one of the seats in the main saloon area. Perfect spot and easily accessible. The water maker will also be fitted into this space which runs under the deck (click here for more on the watermaker)

April 2023

The last little space available in the engine bay was given to the generator battery. Patrick bought a small lead acid battery and a battery box. He fitted a small wooden support which all got bolted down into one of the steel beam.

Another big tick on the To Do List !!